|

AutoFEM Analysis Thermal Contact Between Spherical Surfaces | ||||||

Thermal Contact Between Spherical Surfaces

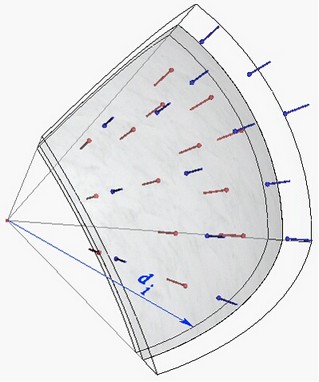

Consider the problem of the steady heat flux in the complex spherical plate with the width ![]() ∑0.5Δd and thermal conductivity coefficients ki

∑0.5Δd and thermal conductivity coefficients ki ![]() , whose first and last surfaces maintain temperatures t1 and tn+1

, whose first and last surfaces maintain temperatures t1 and tn+1![]() , and between the sheets with numbers m-1 and m+1, there is the thermal contact with specific resistance Rm

, and between the sheets with numbers m-1 and m+1, there is the thermal contact with specific resistance Rm![]() (see figure).

(see figure).

The temperature change and thermal flux along the width of the complex plate, consisting of ![]() sheets with diameters d1, d2, ..., dn

sheets with diameters d1, d2, ..., dn![]() and thermal conductivity coefficients

and thermal conductivity coefficients ![]() k1, k2,... kn, respectively, for each sheet

k1, k2,... kn, respectively, for each sheet ![]() fi, i=1,2,..., n are determined using the formula below:

fi, i=1,2,..., n are determined using the formula below:

![]()

Let all sheets, save two ones, are in the ideal thermal contact along the boundary surfaces, and put thermal resistance Rm ![]() between sheets numbered m-1 and m+1; then the thermal flux will be uninterrupted at the transition from one area to the other and, in this case, it will be the same in any point (i.e. f1=f2=...=fn=fl). The temperature change between the opposite surfaces of the entire complex plate will be equal to the sum of temperature changes in separate sheets:

between sheets numbered m-1 and m+1; then the thermal flux will be uninterrupted at the transition from one area to the other and, in this case, it will be the same in any point (i.e. f1=f2=...=fn=fl). The temperature change between the opposite surfaces of the entire complex plate will be equal to the sum of temperature changes in separate sheets:

![]()

Hence

![]()

![]() ,

,

![]()

Assume the following initial data: number of sheets is n=2 ![]() , diameters

, diameters ![]() d1, d2, d3

d1, d2, d3![]()

![]() of each sheet equal 350; 380; and 420 mm, respectively. Applied temperatures t1

of each sheet equal 350; 380; and 420 mm, respectively. Applied temperatures t1![]() and t4

and t4![]() are 473K

are 473K![]() and 273K

and 273K![]() , respectively. Thermal conductivity coefficients are:

, respectively. Thermal conductivity coefficients are:

![]()

![]()

![]()

(steel and aluminum alloy).

Thermal resistance ![]()

![]() (it is approximately equivalent to the thermal resistance of the spherical air layer with the width 0.05 mm and

(it is approximately equivalent to the thermal resistance of the spherical air layer with the width 0.05 mm and ![]()

![]() )

)

Thus,

![]()

![]() ,

,

![]()

![]() ,

,

![]() .

.

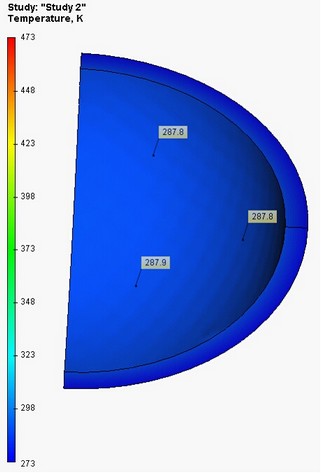

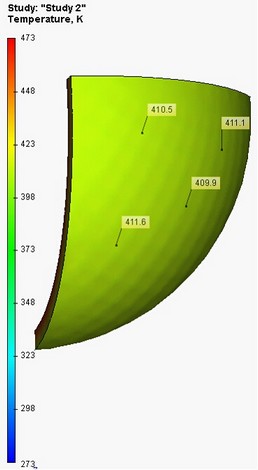

By calculation with the help of AutoFEM Analysis, we have obtained the following results (for the lower and upper sides of the contact, respectively):

Table 1*

FEA Mesh Parameters: |

|||

Results |

Numerical result, |

Analytical result |

Error |

Temperature, t2 |

|

|

|

Temperature, |

|

|

|

Table 2*

FEA Mesh Parameters: |

|||

Results |

Numerical result, |

Analytical result |

Error |

Temperature, t2 |

|

424.7 |

|

Temperature, |

|

|

|

*The results of numerical tests depend on the finite element mesh and may differ slightly from those given in the table.

Read more about AutoFEM Thermal Analysis