|

AutoFEM Analysis Introduction | ||||||

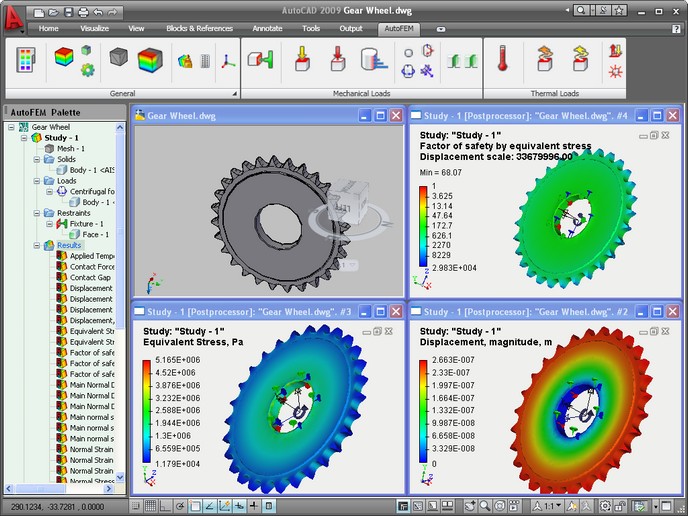

AutoFEM Analysis provides easy-to-use yet powerful design analysis tools for designers and engineers that help them improve design quality, avoid field failures, reduce material costs, and shorten time-to-market. AutoFEM Analysis add-on application is integrated in AutoCAD and performs static, frequency, buckling and thermal analysis. AutoFEM makes it possible to perform design iterations quickly and inexpensively on computer models instead of on costly physical prototypes.

AutoFEM Analysis offers a wide spectrum of powerful tools to help engineers to perform virtual testing and analysis for predicting the physical behaviour under various loading conditions.

Fully integrated with AutoCAD modelling software AutoFEM Analysis allows you to test a design and run multiple iterations without ever leaving AutoCAD.

AutoFEM utilizes the AutoCAD Model Tree, Properties dialogue boxes, command and menu structure, and many of the same mouse and keyboard commands, so anyone who can design a part in AutoCAD can analyse it without having to learn a new interface. Plus, since AutoFEM uses native AutoCAD geometry, design changes made in a model are automatically updated for analysis calculations.

Regardless of industry application, from aerospace to machine-tool, AutoFEM Analysis provides significant product quality benefits; enabling engineers to go beyond hand calculations and verify proof of concept for their designs. Quick and inexpensive analysis often reveals non intuitive solutions and benefits engineers by providing them with a better understanding of product characteristics.

Field failures can lead to costly recalls and liability issues. AutoFEM Analysis shows how a model will perform under real-world conditions before it is built. The ability to perform quick and inexpensive design iterations prior to releasing the design has become a critical competitive advantage. AutoFEM Analysis enables designers to meet functional design specifications but not waste materials helping to reduce cost of production, shipping, and packaging.

All calculations rely on the finite element method (FEM). At the same time, an associative relationship is maintained between the three-dimensional model of a part and the finite element model used in calculations. Parametric notifications of the original solid model are automatically propagated into the meshed finite element model.

•Static analysis allows calculating the state of stresses and strains in a structure under the impact of constant in time forces applied to the model. It is also possible to account for stresses building up due to thermal material expansion/contraction, or for structural deformations introduced by known displacements. By using the "Static analysis" module, the user can evaluate the strength of a structure developed by him, with respect to admissible stresses, identify the most vulnerable parts of the structure and introduce the necessary changes, optimize the design.

•Fatigue analysis is the add-on for the Static Analysis module.Fatigue Analysis is used for the estimation of the cyclic load influence on the factor of safety of structure. This type of calculation is often used in mechanical engineering and building.

•Frequency analysis allows calculating natural (resonant) frequencies of a structure and the respective vibration modes. Based on the calculation results, the product is assessed on the presence of resonant frequencies in the operating frequency range. The developer can enhance reliability and performance of a product by optimizing the design in such a way as to exclude resonance occurrences.

•Buckling analysis is important when designing structures, whose operation implies lasting influence of loads ranging in intensity. With the help of this module, the user can evaluate safety margin by the so-called "critical load". Significant nonelastic strains may occur suddenly within compressed parts of a structure, which could likely cause its rupture or serious damage.

•Forced harmonic oscillation analysis allows for the calculation of amplitudes of the steady forced oscillations of a mechanical system, on which the harmonic compelling force acts, or at the displacement of the basis in accordance with the harmonic law.

•Dynamic Analysis (Direct Integration, Mode Superposition) - simulates a structure behaviour under the action of forces varying in time.

•Thermal analysis is the module providing the capability of evaluating a heated product behaviour under the impact of sources of heat and radiation. Thermal analysis can be used independently for calculating temperature and heat fields through the volume of a structure, as well as in combination with static analysis for evaluating thermal deformations building up in the product.

AutoFEM Lite

AutoFEM Lite offers an easy-to-use first pass finite element analysis tool for every AutoCAD user. It is provided for every license of AutoCAD at no cost.

AutoFEM Lite uses the same design analysis technology that professional Analysis uses to perform all kind of finite element analysis:

However AutoFEM Lite has some limitations its functionalities such as kinds of the boundary conditions or some calculation features.

More advanced analysis capabilities are available within the commercial AutoFEM line of products.