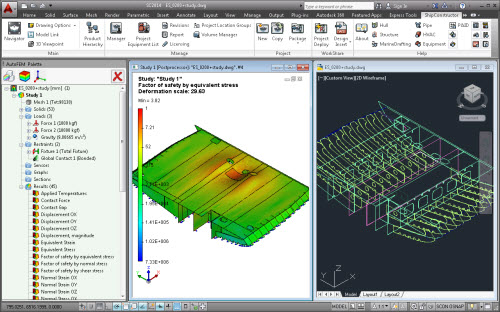

New Features of AutoFEM Analysis 2.9

Supporting AutoCAD 2017 and ShipConstructor 2017

Version 2.9, AutoFEM Analysis is compatible with ten different versions of AutoCAD, namely: AutoCAD 2007-2010 and 2012-2017 which all work in the Windows XP/Vista/7/8/10 environment. Also they work with ShipConstructor 2015R2-2017R2 (excluding AutoCAD2015).

Improved detection and exclusion of unfixed and non-contact parts

Detection of unfixed and non-contacting parts of simulated structures is significantly improved in the version 2.9. Now the system detects correctly non-contacting parts even if they belong to a multi-volume body. In version 2.8, such bodies were considered as being in contact if at least one fragment of the multi-volume body was in contact with other parts of the structure. Therefore, the user is now able to effectively exclude from the calculation the "dangling" fragments of multi-volume bodies and perform the stress state calculation of the structure in spite of the presence of "flying" parts in the study.

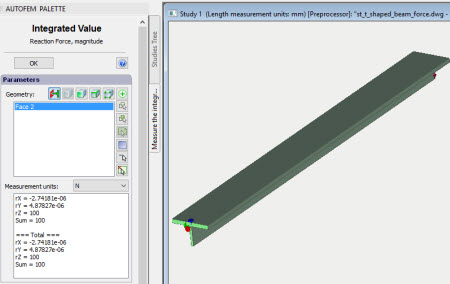

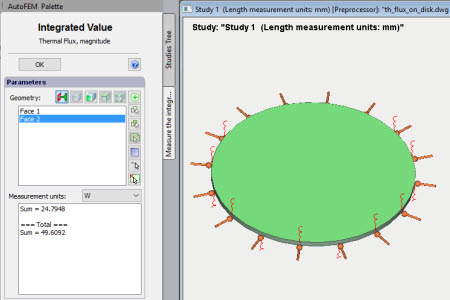

The command "Measure"

A set of special tools for selecting model entities has been added in the dialogue of the command "Measure". Now the user is able, for example, to select just one or several desirable boundary conditions to obtain the integrated value of Reaction Force or Heat Power. These options considerably facilitate the use of the command "Measure".

Additional selection tools have been added in the dialogue of the Reaction Force measure command

Additional selection tools have been added in the dialogue of the Thermal Power measure command

Prefix name of Study Type for Study names

To improve the user perception of study types, the principle of automatic study naming is changed. Now, immediately after the graphical icon of the study type, the full text name of the created study type is displayed that makes the study name more visual and informative.

Names of studies now include the name of study type

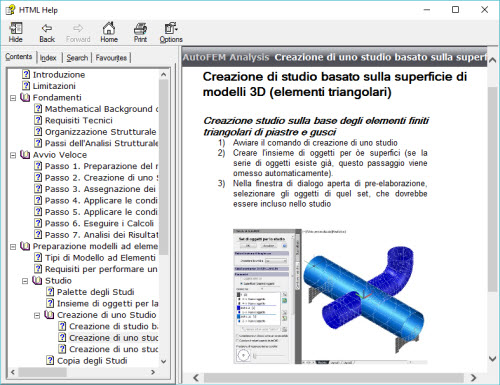

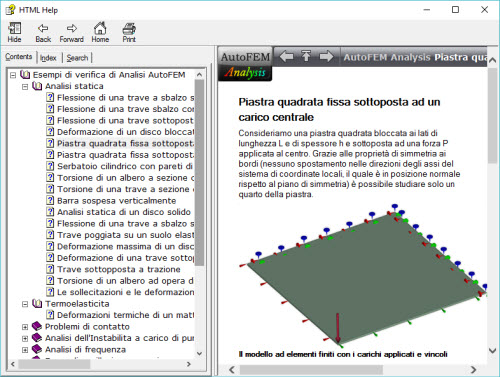

Full text help in the Italian language

AutoFEM version 2.9 includes full text help in the Italian language.

Extended verification tests in the Italian language

Extended verification tests with detailed descriptions in the Italian language are now available.

New features of AutoFEM Analysis 2.8

Support of AutoCAD 2016 and ShipConstructor 2016

Version 2.8, AutoFEM Analysis is compatible with the nine different versions of AutoCAD, namely: AutoCAD 2007-2010 and 2012-2016 which all work in the Windows XP/Vista/7/8 environment

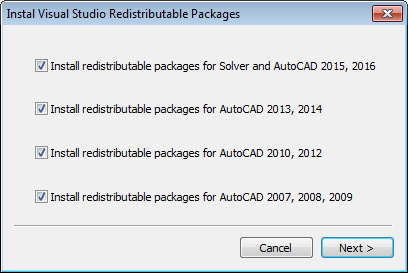

AutoFEM Analysis Installer is improved

An installation of compulsory program components (Microsoft Visual Studio redistributable packages) was added to the AutoFEM Analysis Installer, which was necessary to make the system work. The installer determines which version of AutoCAD and offers to the user the installation packages necessary to work with the given version of AutoCAD.

The dialogue of installation of the necessary Microsoft components

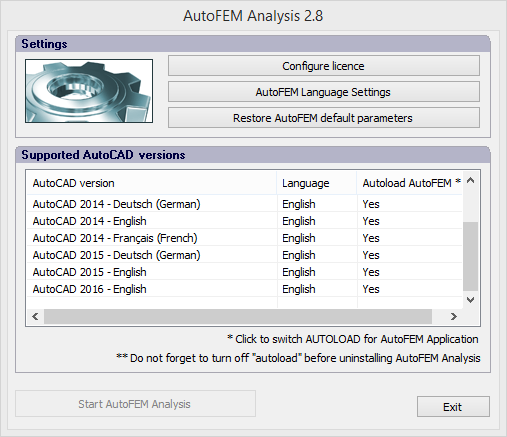

Dialogue of program launch

The application launcher was improved. In particular, on default, the mode of AutoFEM launch as "autoload" is installed now (i.e. the download of AutoFEM into AutoCAD together with the each AutoCAD launch)

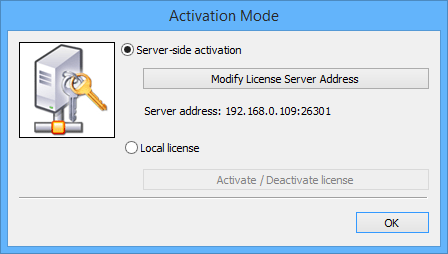

In addition, all actions to set up the licence and manage the work with licences, such as "Activation/deactivation" of the licence, are available now from the start dialogue after pressing the button "Configure licence" (previously, they were only accessible from the Windows menu).

Dialogue of managing the licence type (server-side or local one) and of activation/deactivation of the licence

New functionalities of the Preprocessor

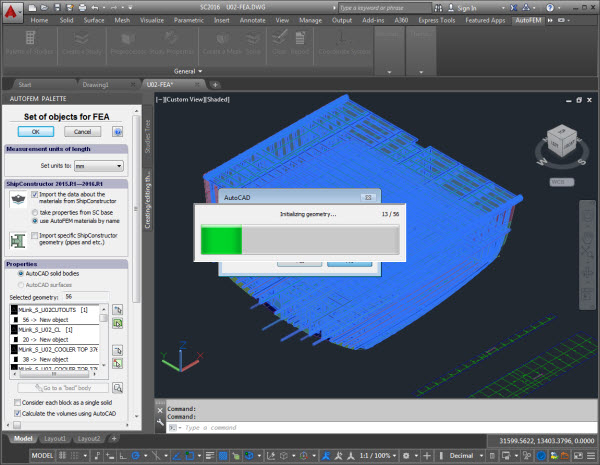

Using Progress bars when fulfilling operations of data processing

Most operations which take long time to be fulfilled in the case of large models (for instance, acquiring the model from AutoCAD in the process of creating the set of bodies for FEA) now use Progress bars which visualize the current stage of the program work and allow one to estimate the remaining scope of work before the end of the operation. The Progress bar reflects the number of the already worked-through objects and allows one to indirectly estimate the time necessary to complete the current stage.

Progress bars illustrate the current state of acquisition of the 3D model from AutoCAD

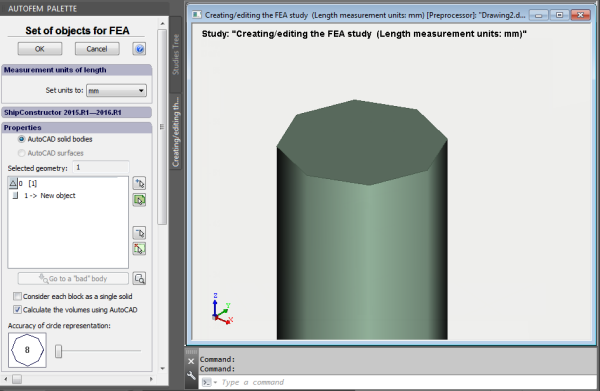

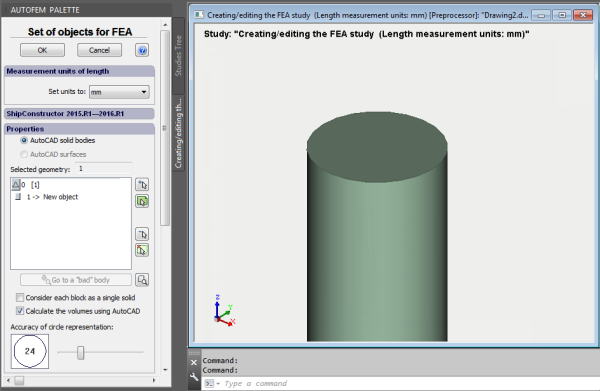

Dialogue of the command " Set of Objects for FEA" is improved

The ability to manage the smoothness of the imaging of cylindrical and spherical surfaces in the Preprocessor window is now added at the primary acquisition of the 3D model geometry from AutoCAD. The special slider allows the user to set a desirable minimum accuracy of approximation of curved elements of the 3D model.

A cylinder of small diameter is approximated as an octagon

A more accurate approximation of the same cylinder by a polygon with 24 segments

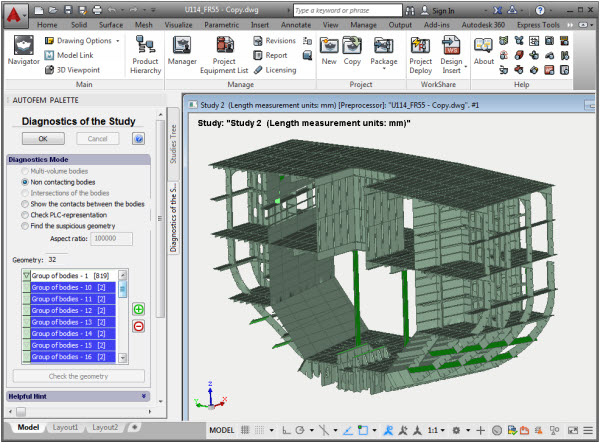

New abilities for the command “Diagnostics of the Study”

Excluding dangling bodies from the calculation

The command “Study Diagnostics” has acquired the ability to exclude dangling bodies and groups of bodies from the calculation without their withdrawal from the study. "Dangling” parts mean single parts or small groups of parts which do not make contact with other parts of the 3D assembly, i.e. those which appear to “hang” in the air. Such objects would not directly contribute to the mechanical strength computations, if not attached in some way they would fly to “infinity” when forces were applied to them. This option makes it possible to perform the strength calculation, even if there were multiple, separately located unfixed objects present in the 3D model (and they might be overlooked).

Dangling bodies are marked in green in the Preprocessor window

New abilities for the mesh generator

Accurate workings with Multi Volume objects

The new version of the mesh generator permits the use of so-called multi volume bodies in the studies (i.e. bodies comprised of several different volumes without points of contact between them). It significantly simplifies the preparation of the computation model in the case of the presence of multi volume bodies. In the previous versions of AutoFEM, the presence of multi volume bodies was an insurmountable obstacle in the way of creating a finite-element mesh.

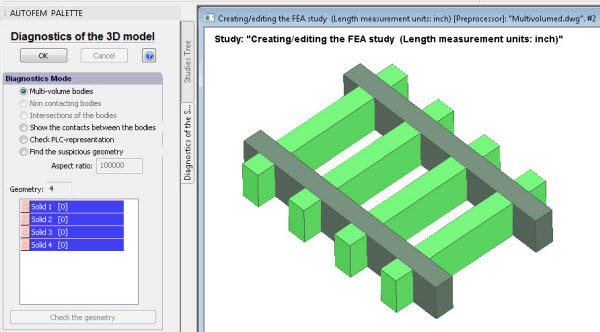

Diagnostics of a 3D model with multi volume bodies as per previous version

Presence of multi volume bodies is now no hindrance to creating a finite-element mesh

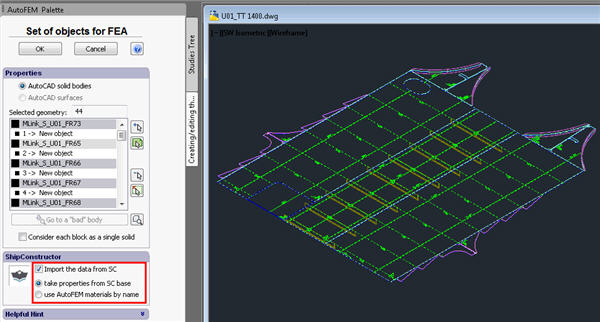

Improvements in working with ShipConstructor

Efficient working with large models in ShipConstructor

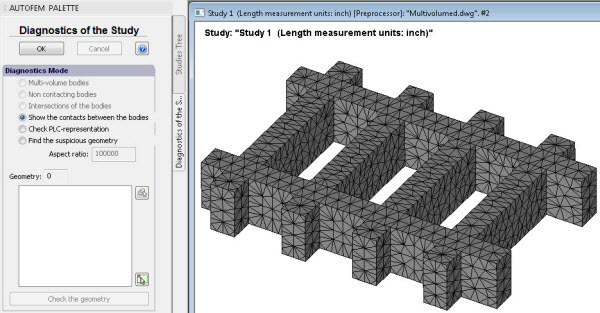

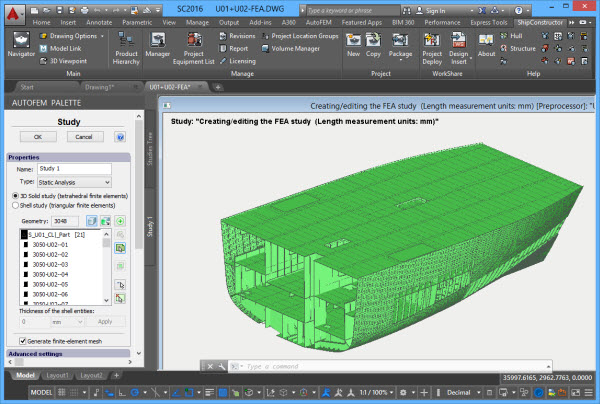

Due to the improved working of some functions of AutoCAD, starting from the version of AutoCAD 2015 and especially AutoCAD 2016, AutoFEM Analysis now is able to efficiently process very large assembled 3D models of ShipConstructor, usually containing thousands of 3D models of parts.

AutoFEM Analysis can now process assemblies containing thousands of objects, including the hulls of sea vessels

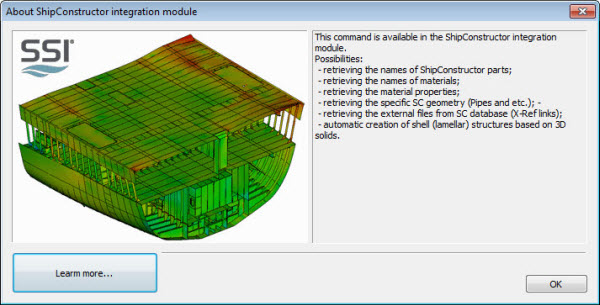

Improvements to the module of integration with ShipConstructor

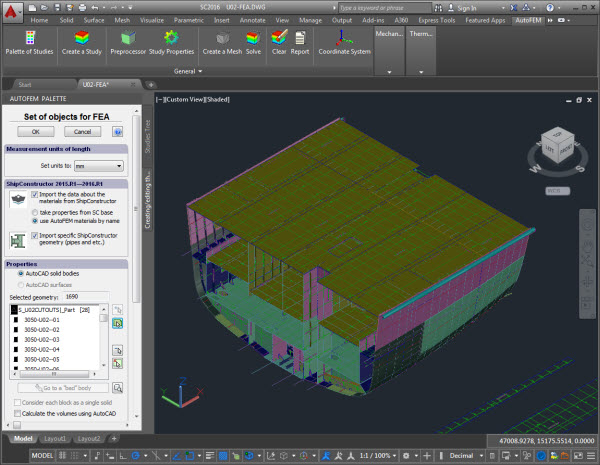

The option of acquiring specific geometry like that of ShipConstructor was improved. We mention the specific geometry parts which cannot be selected for FEA analysis by standard means using AutoFEM, because they have a specific type, which does not coincide with the type of 3D solid in AutoCAD. This option, in particular, allows one to obtain the curved geometry of the underwater parts of sea vessel hulls, pipeline parts and to manage the list of obtained objects.

The improved dialogue of integration with ShipConstructor

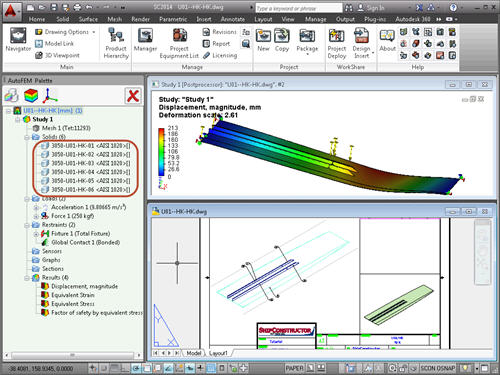

Working with the hulls of sea vessels

An entire set of dedicated tools for working with hull parts of sea vessels was specially developed to satisfy the needs of shipbuilding engineers who use ShipConstructor. We recommend that laminar finite-element representations of calculated models, created on the basis of 3D solid-body models of designs are used as the main technique for strength analysis of solid hull units of sea vessels.

Version 2.8 offers these dedicated set of tools, providing the ability to create studies with the hulls of sea vessels, with an account of the specific representation of these designs, which are used in ShipConstructor.

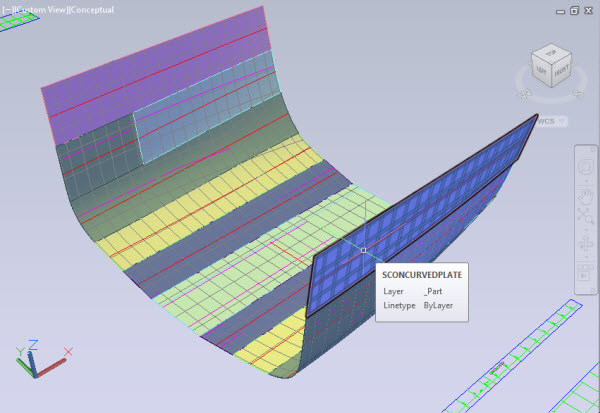

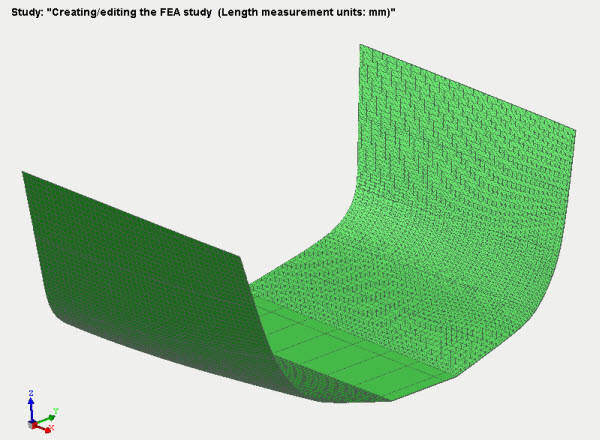

Creating studies with hull-like objects

The curved hulls of sea vessels in ShipConstructor are represented with the help of objects of special type. For these purposes, the class of objects (SCONCURVEDPLATE) is created, representing the curved geometry as the aggregate of triangular or rectangular facets which have the thickness. In the course of acquiring a 3D model from AutoCAD, AutoFEM Analysis 2.8 correctly unites the aggregates of these facets in a single, uniform facet, which makes it possible to set boundary conditions, applied to these elements of the design.

The hull of a sea vessel in the window of AutoCAD/ShipConstructor

The hull of a sea vessel in the window of the Preprocessor of AutoFEM Analysis

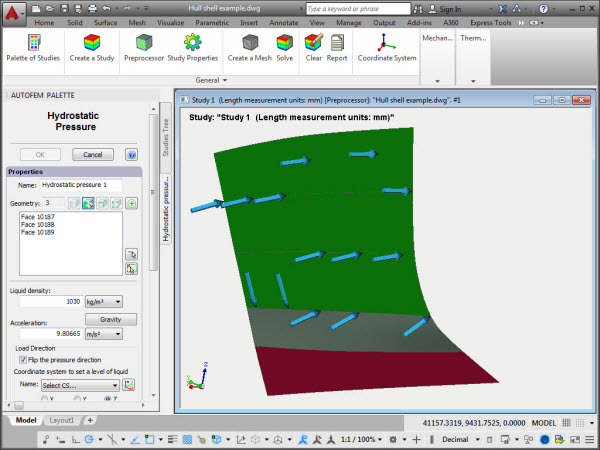

Application of distributed loads to hulls of sea vessels

When creating a study in the laminar finite-element setting, the system automatically groups the facets, describing the geometry of a sea vessel hull, in a generalized face that allows one, in one click, to choose these design elements in order to apply the distributed boundary conditions to them (pressure, force and so on).

Applying the load “Hydrostatic pressure” to elements of a ship’s hull

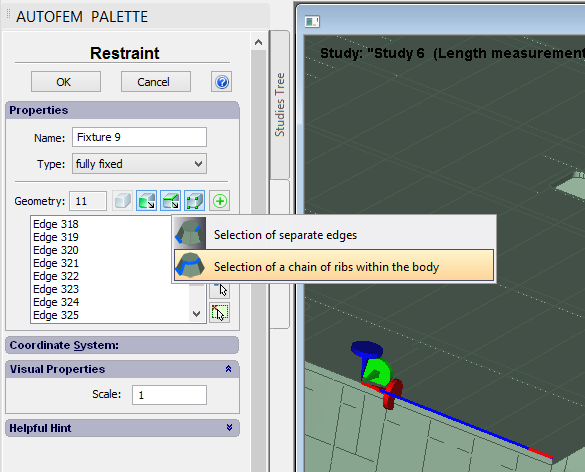

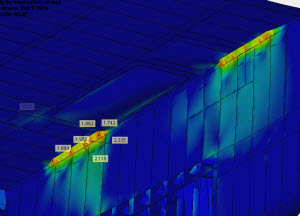

Setting boundary conditions for chains of edge segments

When working with finite-element models based on plates, the boundary conditions are applied to facets and edges. The dedicated tool set allows easier application of the boundary conditions to edges and, thus, for the selection of a set of segments of one edge by stating the first and last (or next) segments. The system automatically adds all intermediate segments belonging to a single body. This functionality makes it possible to apply boundary conditions to the edges of hulls, containing a few or hundreds of separate segments.

Selection of a chain of edge segments for setting a boundary condition

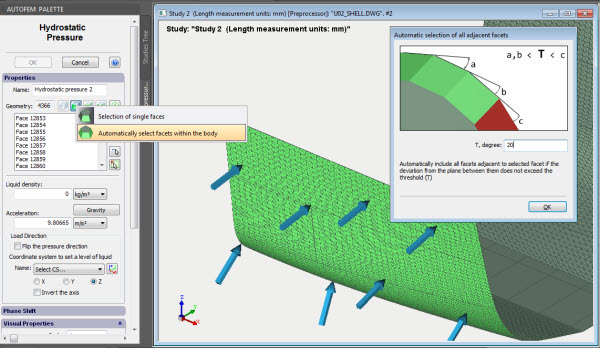

Setting boundary conditions for the curved surfaces of hulls

Concerning the loads applied to facets (force, pressure, torque, bearing load, and additional mass), there is a new option to select, in one click, the complete surface of the part, even if it is divided into multiple facets. This is typical of units of the hull type, created in ShipConstructor. In a special dialogue window, the user sets out the permissible deviation from the normal (in degrees), based on which the system will automatically select facets, whose deviations from the normal are no greater than the set value, and applies the boundary condition to all the aggregate of the facets by one click.

Automatic selection of the curved facet of a unit, approximated from many facets

A new approach to modelling thin-wall designs

Automatic transformation of a volumetric finite-element study into laminar one

Most typical designs in the shipbuilding industry (construction of sea vessels and coastal facilities) 90-95% of them are made of steel sheets and profiles. It is generally known that the finite-element analysis of such designs using 3D finite elements (such as tetrahedrons or hexagons) is often hard to produce from the computational stand (i.e. they require too many computational resources). In the theory and practice of finite-element computations, it is generally acceptable to use finite elements of plates (shells) of triangular or rectangular shape for the estimation of the tension state of such designs.

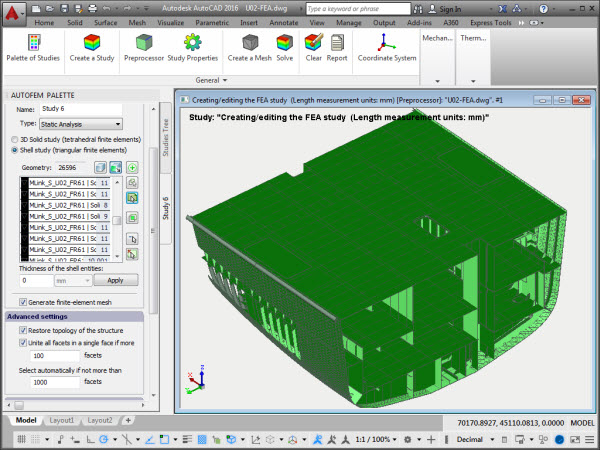

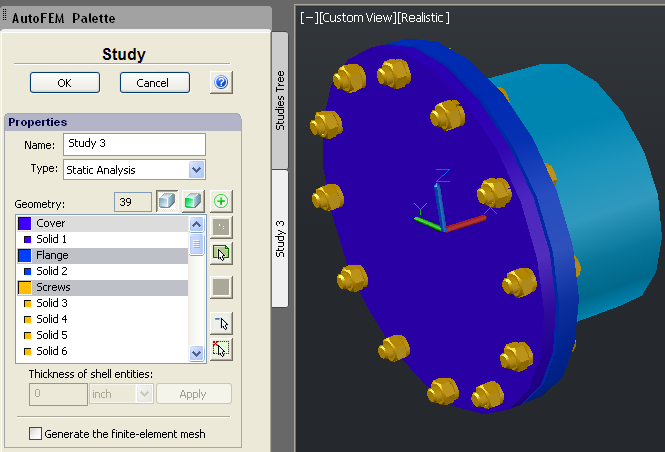

In version 2.8, the dialogue used for creating the study, visually reflects the selection of a finite-element setting (3D or laminar), in which the user wishes to create a finite-element study. For modelling solid designs of ships, which are mostly fabricated from sheet metal parts, we recommend that finite-element modelling by laminar elements is used.

Choice of the option for creating a shell study from a solid-body 3D model

In AutoFEM Analysis 2.8, an intellectual algorithm is implemented, which allows one to automatically build the computational model using triangular finite elements of plates for designs made of 3D solids.

The logic of the algorithm is that all elements of the design can be considered as laminar parts. The system analyses the geometry of the part and automatically selects the part surface with the greatest area to be included in the computation. When selecting the facets of the 3D solid, the mutual location of the part relative to other contacting parts is taken into account. As a rule, a facet with the greatest number of contacts with the neighbouring parts is selected for computation. The system will automatically determine the thickness of the laminar part. The user can change both the automatic selection result (i.e. select or add another facet in the computation) and the thickness assigned to the specific part by the system. This allows the computer to flexibly adjust the laminar finite-element model, while striving for the greatest degree of correspondence in the calculated model to its solid-body original prototype. In the process of the automatic construction of the equivalent laminar model, the system analyses the mutual location of the design’s parts and provides for a better preservation of the topology of the entire design, that means that parts in contact in the initial solid-body 3D model will, as far as it is possible, remain in touch in its laminar approximation. The user can manage this process, switching on or off the option called "Restore topology of the structure" in the dialogue of creating the study. The same dialogue sets options for automatic unification of facets in the uniform facet and for a threshold of the permissible number of facets for the automatic selection of the geometry to be included in the study.

Options of the command of creating the shell finite-element study, based on facets of 3D solids

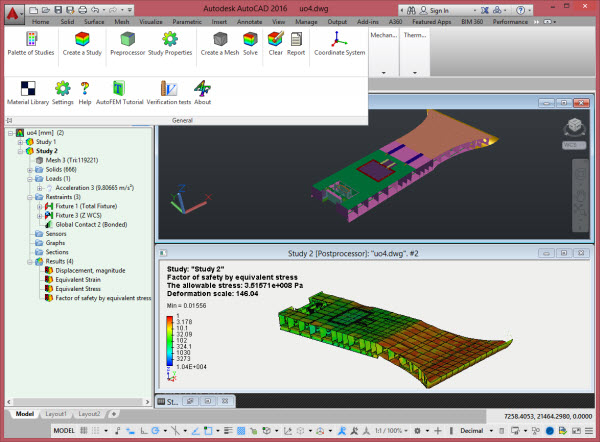

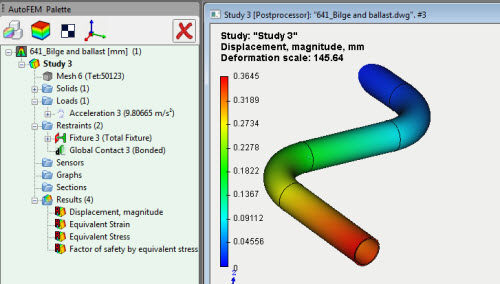

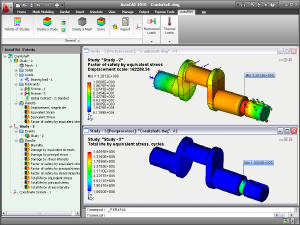

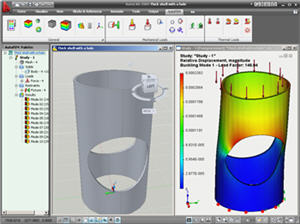

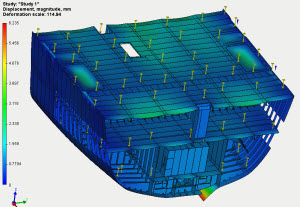

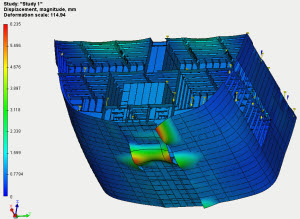

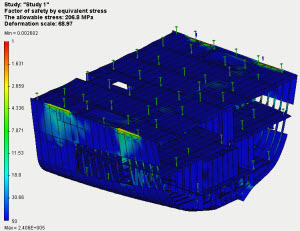

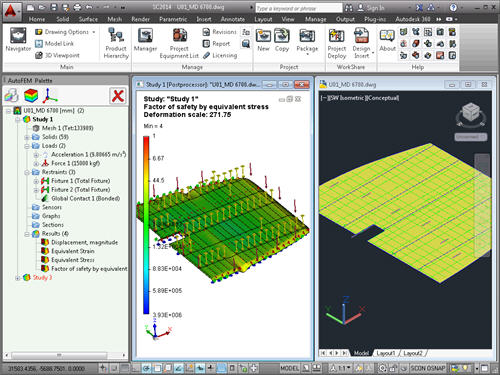

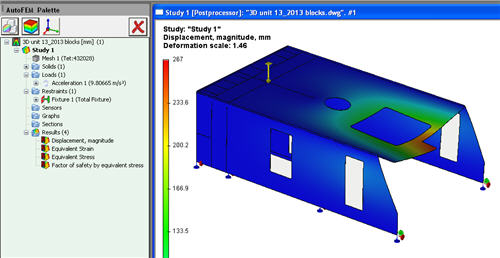

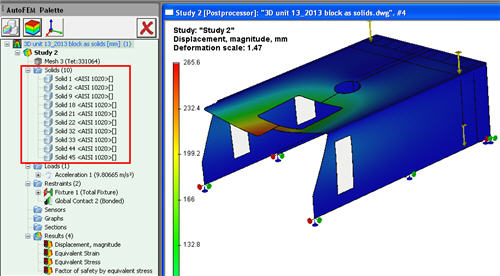

Displacements of a vessel unit lifted with ropes

Factor of safety of the lifted ship structure

This functionality is available together with the licence for the module of integration with ShipConstructor and allows the user to obtain in one click the laminar finite-element approximation of the initial 3D volumetric model of the design built in ShipConstructor.

The dialogue listing basic functions of the SC integration module

Considering the analysis of large-size sheet designs, the main advantages are as following:

• Much less severe requirements of the available computational possibilities when analysing large-size ship designs. Though, in the case of building an adequate finite-element model, reliability of the computational result corresponds to common techniques, used to analyse designs usual for shipbuilding.

• Relative simplicity in building the finite-element model, computational mesh and the setting of boundary conditions.

• The possibility of editing manually the finite-element study to achieve the most acceptable and reliable result.

New possibilities for the Postprocessor

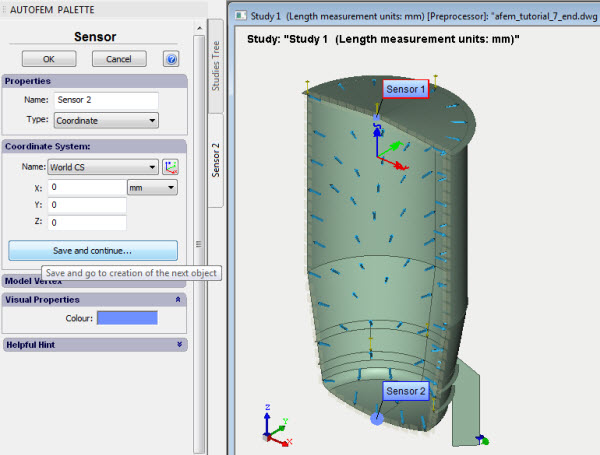

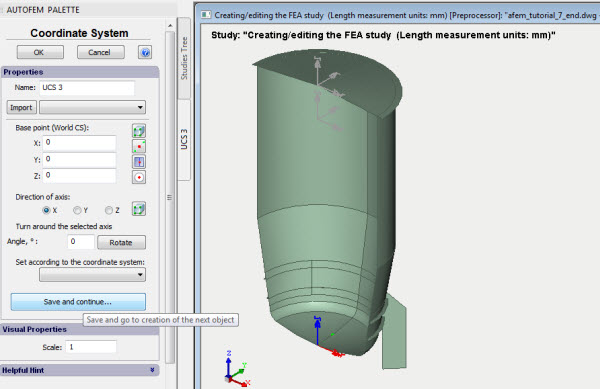

Improvement of commands in creating sensors and user-oriented coordinate systems

The commands for creating sensors and user-tailored coordinate systems now have the ability to create several sensors or coordinate systems while the command is retrieved once. The dialogue has a new button  , which allows one to save the current definition of the object and go on to the creation of the next object, not dropping out of the dialogue. It significantly accelerates the work, especially concerning large models.

, which allows one to save the current definition of the object and go on to the creation of the next object, not dropping out of the dialogue. It significantly accelerates the work, especially concerning large models.

Creation of several sensors with one click of the command

Creating several user coordinate systems with one click of the command

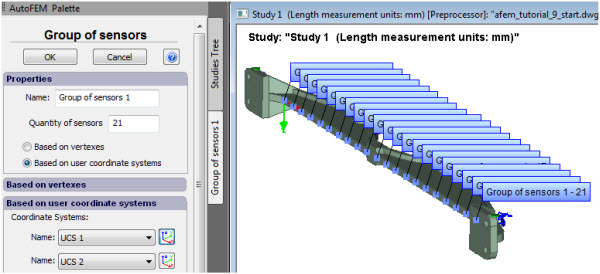

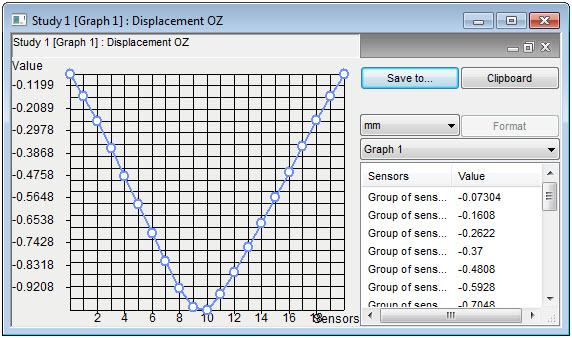

Group of sensors

This new command allows one to create a group of sensors, positioned along one right line, in one click. So the created sensor group can be used to construct a graph of the result. The user must specify the total number of sensors and limits of the model or coordinate systems, in-between which the sensors are located.

The Group of sensors allows the user to define points for obtaining data to plot a graph

The graph of the result, drawn on the basis of the sensor group

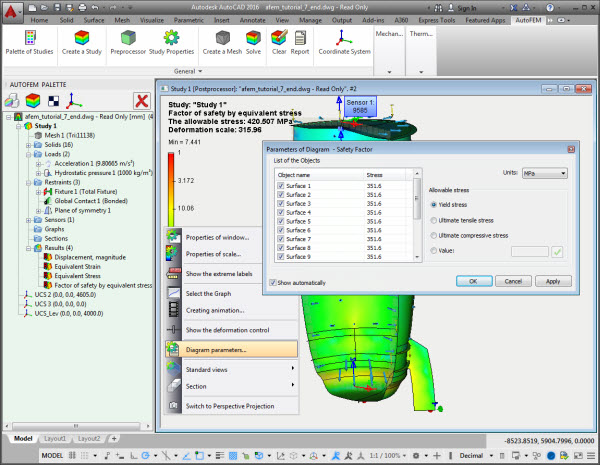

New dialogue of the result, called “Safety Factor"

The logic of work of the result tuning command "Safety factor " was radically reorganised. This dialogue allows one to flexibly manage and produce a visual of the levels of permissible stresses, used to test the designs for strength. In the dialogue, the level of permissible stress is shown for each part. The user can exclude separate parts from the computation, set user values of permissible stresses and change units of measurement.

The new dialogue of result parameters “Safety factor” in terms of stresses

Improvement of the User Interface

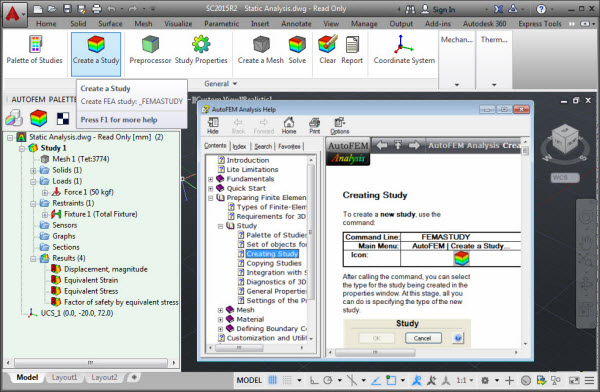

The button F1 calls reference for the command from the AutoFEM ribbon. The possibility of opening the context reference using the button F1 (the mouse is directed to the button) in the ribbon of AutoFEM Analysis basic commands.

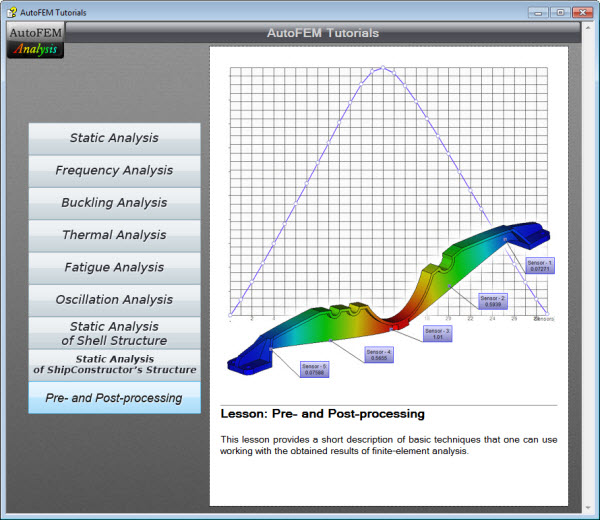

A new lesson in AutoFEM Tutorials

The training course of AutoFEM Analysis now includes a lesson for working with the Preprocessor and Postprocessor of the system, showing a step-by-step guide and illustrating how properties of Preprocessor and Postprocessor windows can be tuned, sensors and coordinate systems can be created, graphs of results can be constructed, etc. In addition to a step-by-step illustrated manual, the lesson contains several videos demonstrating the basic methods of work.

Lesson for working with Preprocessor and Postprocessor of AutoFEM Analysis

New type of licensing is available

In addition to perpetual licence model, a new way of licensing is available now: 1 year subscription. This type of licensing is suitable for Autodesk users who use a subscription model of Autodesk products licensing. The price for a single calculation module starts from 795 Euro/USD for 1 year subscription or just ~66 Euro/USD per month (VAT not included). More detailed information can be found here.

AutoFEM Training Course

A joint - AutoFEM Software & NDAR - AutoFEM training course will be held in NDAR office (Antibes, France)

on 31 March-02 April 2015.

The course will be held in English, and other languages will be supported (French, Italian).

The course is for beginners and intermediate users of the program, and those interested in FE structural analysis. The materials covered include:

- Program environment and GUI, settings

- Types of studies

- Pre-processing: meshing , boundary conditions, materials

- User Coordinate systems

- ShipConstructor integration

- Processing, solver types

- Post processing: using sensors, graphs, colour diagrams, result sampling, reports

An AutoFEM license will be provided during the course free of charge. Participants should bring their laptops which should be running AutoCAD (Note AutoCAD 2011 is not supported). Although training models will be provided, participants are encouraged to bring their models, in order to work hands-on their own projects. Registration will be accepted on a first come first served basis, places are limited.

All course participants will be entitled to 20% discount in the purchase of software.

For more information or logistics questions, please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

Looking forward to seeing you at the course,

Contact persons:

Stéphane DARDEL. Nick DANESE

Design Systems & Technologies ™

150 rue de Goa, 06600 Antibes, France

tel +33-4-9291 1324 / fax +33-4-9291 1338

This email address is being protected from spambots. You need JavaScript enabled to view it. / www.ndar.com

New features of AutoFEM Analysis 2.2

Integration with ShipConstructor

Based on AutoCAD, ShipConstructor is the leading software product for ship design and ship building, adopted worldwide. ShipConstructor provides the tools needed to design, model and prepare production documentation for any type of vessel, be it a ship, a submarine or an offshore platform.

In the course of designing a vessel or an offshore structure, it is necessary to verify its strength and stiffness characteristics, preferably using Finite Element Analysis. Thanks to direct integration of AutoFEM Analysis and AutoCAD, ShipConstructor users can now use AutoFEM to transparently run FEA analysis of ShipConstructor models.

As of AutoFEM Analysis v2.2, the integration with ShipConstructor is complete. The ShipConstructor 2014 stock catalogue supports the mechanical properties of materials needed for FEA, and AutoFEM reads the full model topology directly, including:

• Names of parts

• Names of AutoCAD layers (for parts in the current document)

• Data about the material (name, grade, etc.). If the user has not specified thee, they will be taken from the native AutoFEM Analysis materials library, using a name matching technique.

Settings of integration with ShipConstructor

ShipConstructor parts and all related information are acquired by AutoFEM Analysis, and

if needed, ShipConstructor materials are name-matched with materials in the AutoFEM library.

Calculation example of a ShipConstructor Assembly

More information about joint work of AutoFEM & Shipconstructor can be found here:

AutoFEM Analysis & ShipConstructor Software: Working Together

or here

AutoFEM Analysis & ShipConstructor Software: Working Together (pdf)

Work with the AutoCAD blocks

The new version of AutoFEM Analysis allows the user to work more effectively with AutoCAD blocks. In the process of creating a set of objects for the finite-element analysis, the system analyzes the content of the block and processes each object contained in the block as the individual solid body. Then, each element of the block may have its own material, and one may even carry out an individual analysis for each solid contained in the unit. It is also possible to activate the single-body mode for the unit. In this case, the collection of parts will be considered as one, and the selected material used for all the components (parts).

Processing the group of parts as a unified solid-body object

Calculation example: the block is considered to be one solid body

The block is analyzed as the aggregate of the several bodies composing it,

which were created in AutoCAD

New utility of setting up "FEMA Tool"

Launch of AutoFEM Analysis from the Start menu. The AutoFEM Analysis utility "FEMA Tool" has been completely redeveloped, and AutoFEM Analysis can now be launched directly from the All Programs|Windows menu. In the dialogue, the user chooses the AutoCAD version using which he or she wishes to launch AutoFEM Analysis.

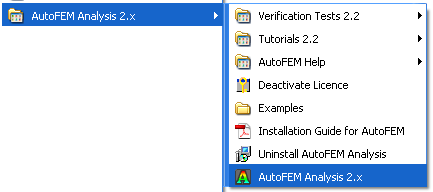

Shortcut for launching AutoFEM Analysis from the All Programs Windows menu

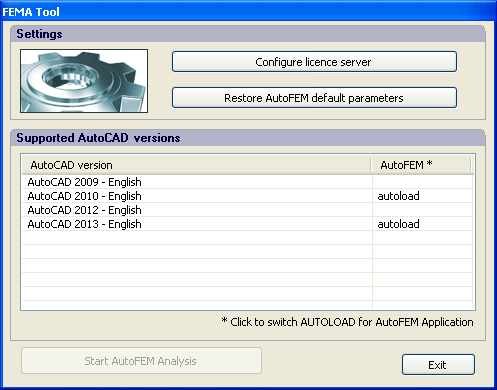

Dialogue hosting the configuration and launching of AutoFEM Analysis

In the "FEMA Tool" utility dialogue, one selects the version of AutoCAD in which to run AutoFEM Analysis, and identifies the licence server by its network address.

Materials: new possibilities

Material parameters shown in user defined units (other than SI)

The materials library now documents the physical properties of materials, in the user-selected system of units. The user-selected unit system is stored by the system and remains available thereafter.

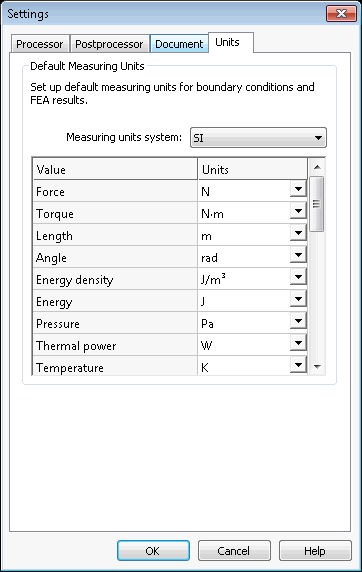

Choosing the unit system

Copying materials

Materials can be copied within the user library. The copies can then be edited to obtain new materials with new physical properties.

Copy of materials and user defined units are available

New ways to work with AutoCAD layers

Using AutoCAD layers for grouping objects within the Study

Objects included in the Study are grouped by layer and identified in the list by the name and colour of the layer.

Objects in the Study are grouped by layer

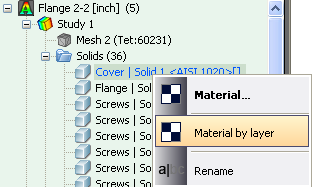

Assigning the material by layer

It is now possible to assign a material in one step to all solids placed in the same layer.

New command "Material by layer"

Assigning the thickness of plate parts by layer

It is now possible to assign a thickness to all structural shell parts located on the same layer.

New command "Thickness by layer"

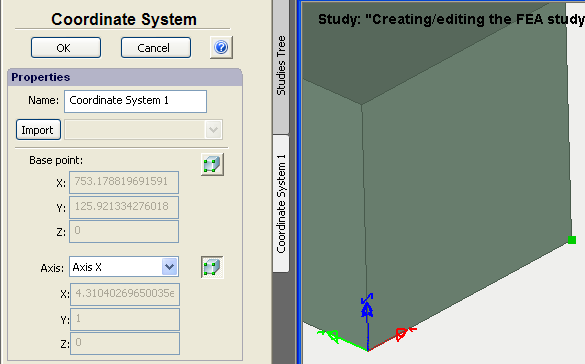

New methods of creating coordinates systems

The command used to create a user coordinate system has been greatly improved.Along with the ability to import coordinate systems from AutoCAD, it is now possible to create and orient the coordinate systems, selecting vertexes of the 3D model in the Preprocessor window.

Use of the 3D model vertexes to define the UCS

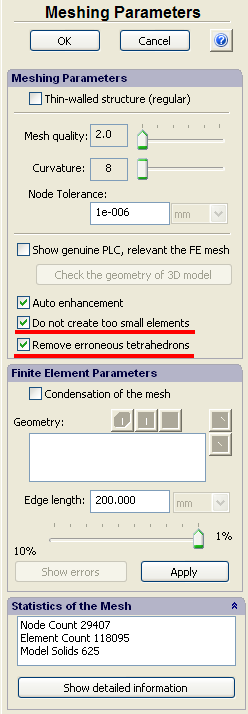

New options to generate a tetrahedral mesh

Two new options have been added to the command used to generate tetrahedral meshes:

Do not create elements which are too small. This option allows restricting the generation of small finite elements in order to decrease the total number of elements and cut the number of the problem dimensions without prejudice to the calculation accuracy. This option is activated by default.

Remove erroneous tetrahedrons.This option automatically removes poor quality tetrahedrons during mesh creation,thereby avoiding the need for geometrical corrections during calculation runs. This permits a more reliable transfer of calculation results from one study to another (for instance, to transfer the results of thermal analysis to static analysis for calculation of thermal elasticity). This mode is activated by default.

New options of mesh generator

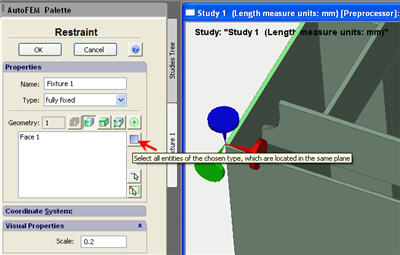

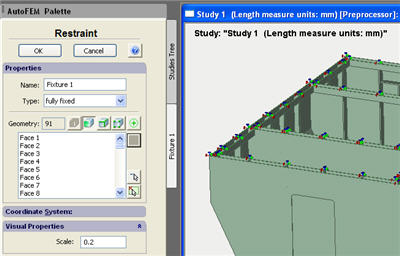

New selection tool to identify objects located in one plane

A new selection tool analyses boundary conditions and finds all the objects lying in one plane. First, one selects the entities of 3D model (facets or two edges located in one plane, or three vertices). Then, using the new selection button, all the coplanar objects from that selection (facet, edge, or vertex) are selected and grouped. This possibility essentially facilitates the preparation of the finite-element model of large assembly structures, consisting of hundreds or thousands of parts.

All facets lying in the same plane as the first selected facet

are automatically added to the list when pressing the button

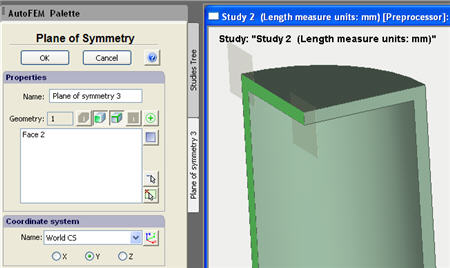

New boundary condition – Plane of Symmetry

This command allows to define the planes of symmetry of a structure, i.e. the planes relative to which the structure’s deformation is supposed to be symmetrical. As a rule, the planes of symmetry are used to cut the dimensionality of a problem being solved, at the expense of the possibility of analysing only one part of the structure. At that, the multiple (at least by 2 times) decrease in the number of algebraic equations (at the same level of discretization) is achieved.

Dialogue of the Plane of Symmetry command

Calculation example: use of symmetry to decrease the problem

New report generation dialogue

Working with the report generation dialog has been made much easier. Management of the output results has been streamlined, and the creation of the 3D VRML model, used to display results, has been improved. By default, the VRML model will not be created if the number of finite elements exceeds 50,000. The user is able to set the threshold value.

New dialog of Report settings

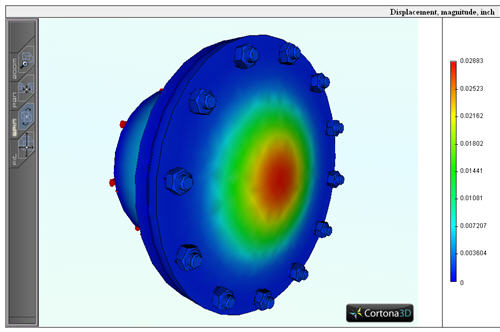

Creation of VRML models of results has been improved

Generating VRML models of results is now optimized as function of visibility.

Non-linearity in static problems for models based on AutoCAD Surfaces

Support of geometric non-linearity now possible for static analysis using shell finite elements.

Geometric non-linearity is supported using plate finite elements (shells)

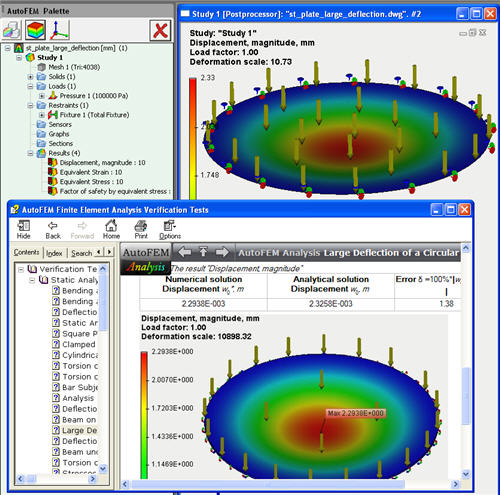

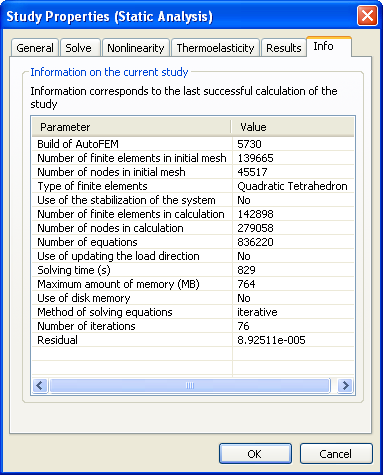

Calculation info

A Study Properties page documenting the result of the latest successful calculation has been added, a very useful reference.

New tab Info contains main information about the solved study

Attention!

If while opening the DWG file, containing the saved studies of previous AutoFEM version, you see the AutoCAD error messages, remove the previous data of AutoFEM Analysis with the help of the command _FEMAERASEALL  and recreate the studies.

and recreate the studies.

{source}

<script src="https://apis.google.com/js/platform.js"></script>

<div class="g-ytsubscribe" data-channelid="UCE62j8F63nM3QX5gsQj0Grg" data-layout="full" data-count="hidden"></div>

{/source}

New features of AutoFEM Analysis 2.5

Support of AutoCAD 2015 and ShipConstructor 2015

Starting with the version 2.5, AutoFEM Analysis is compatible with eight different versions of AutoCAD, namely: AutoCAD 2007-2010 and 2012-2015 which work in the Windows XP/Vista/7/8 environment.

AutoFEM interface language selection

Starting with the version 2.5, the user can arbitrarily launch the software in one of five European languages: English, German, French, Italian or Spanish. On default, the system uses the language of AutoCAD in which it is being launched. If AutoFEM hasn’t a language interface (for example, Turkish), The English version is used. The user can select and set the AutoFEM interface language by pressing the button "AutoFEM Language Settings" and select the desired language. The selected language is assigned for all available AutoCAD versions and reflected in the corresponding column of the start dialogue. It is possible to simultaneously launch several instances of AutoCAD/AutoFEM with different language interfaces, running the AutoCAD/AutoFEM, then to change the language settings and run the next AutoCAD/AutoFEM instance.

Dialogue box of AutoFEM language settings

The selected language is shown in the AutoFEM start dialogue

Improved dialogue box of the command “Set of Objects for FEA”

Measurement units of length. Now, the user can set the length units of the 3D model not only in the document settings but also directly in the process of creating a set of objects for FEA, extremely convenient. In the same dialogue, the user can change the units. On default, the units coincide with AutoCAD units of the current DWG file. The user is able to change these units not only while a set of objects is being created but at any time later in the same dialogue or in the Settings | Document page.

Measurement units can be defined while creating the set of objects for FEA

News of ShipConstructor Integration

Support of specific geometry such as Pipes. The options of ShipConstructor integration have been changed. A new opportunity to load from the ShipConstructor document a specific geometry (such as Pipes) has been added.

Option of the specific geometry import

ShipConstrutor pipes in the Preprocessor window

New iterative frequency / buckling solver

In AutoFEM 2.5, a new frequency and buckling solver is presented. Now the user can select between two methods of solving these problems - Direct (Lanczos algoritm) and Iterative.

Direct (Lanczos algorithm) uses a full inversion of the matrix to find the frequencies, therefore, it usually requires more random memory than the iterative method. It works fairly quickly to solve relatively small problems on powerful computer systems.

Iterative solver has lower memory requirements than the direct method because the inversion of the matrix is not needed. Therefore, it allows you to solve large frequency/buckling problems. The volume of studies is limited only by the calculation capabilities of the computer system, (first of all, available RAM and ROM).

New dialogue box of the frequency solver

New dialogue box of the buckling solver

Settings of a new frequency / buckling iterative solver

Searching for frequencies in the range

The possibility to seek resonance frequencies inside the defined frequency range by the user has been provided. The user should specify the lowest and highest frequencies and the number of them to be found. The system will seek resonance frequencies in the specified range.

The dialogue box of the interval frequency solver

Common finite element mesh for several studies

AutoFEM allows the user to copy existing studies and use a copy as a base for a new finite element study. Since version 2.5, the user has the opportunity to control whether the original study and its copy have a common (single) finite element mesh, or if they are independent. On default, the system offers an independent finite element mesh for the copy of the original study.

Dialogue box for selection the mode of the command “Copy”

There are two available modes to copy the finite element mesh of the original study.

Create a new independent copy of the finite element mesh (default mode). It this case, each study (original and its copy) will have an independent finite element mesh. The user can recreate or edit the mesh in the copy of the original study to get different calculation results. This mode is often used to carry out several calculations with the different mesh size to confirm the convergence of the finite element solution to a stable value.

Use common finite element mesh for original study and its copy. In this case, the original study and its copy have a common (single) finite element mesh. Changing the parameters of the mesh influences both studies simultaneously and immediately. This mode is useful for combined calculations, for instance, when the results of the thermal study must be transferred to the static study and the finite element meshes must coincide. To destroy the link between meshes, delete the mesh in the desirable study and create it anew.

New service command «Physical properties”

This special command allows the user to get the values of the mass-volume properties of the selected objects (solids or surfaces). The command is available from the contextual menu on the selected object in the tree of studies or in the Preprocessor window. The command calculates volume / area / mass (if the material has been assigned) of the finite-element representation of the original objects and compares these original parameters with the same parameters calculated by AutoCAD functions for the original AutoCAD geometry. The difference between these values helps estimate the accuracy of finite-element representation of the simulated structure.

Retrieving the command "Physical properties"

Depending on the geometry selected for the finite element study, three types of the result table are available.

Table of volume-mass properties of the study based on 3D solids

New additional option of 3d model diagnostics

Mode Find suspicious geometry. This mode allows the user to find very small entities of the 3D model such as extremely small steps, fillets or chamfers, which can prevent the successful creation of the tetrahedral finite element mesh (the mesh generator cannot divide them into tetrahedrons). If the mesh is not created, you should modify these elements of geometry to eliminate errors. The aspect ratio defines the threshold value when the object may be considered as an erroneous object.

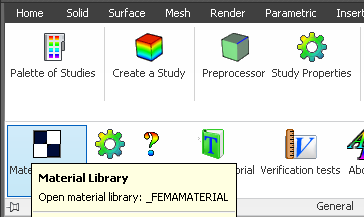

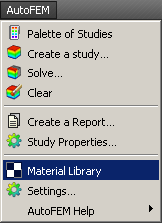

New access to the AutoFEM material library

Access to the AutoFEM material library has been facilitated. Now the user can open library of materials by three ways: using main AutoFEM menu, AutoFEM Ribbon or the button of a quick access on the top of the AutoFEM Palette.

New ways of the access to the AutoFEM material library

AutoFEM Help in the Spanish language

Full text and context dependent help is now available in the Spanish language.

AutoFEM Help in the Spanish language

New lesson on AutoFEM & ShipConstructor Integration

A special interactive lesson on the theme of AutoFEM & ShipConstructor Integration has been added in AutoFEM Tutorials

New lesson about joint work with ShipConstrutor

Many other small and medium improvements have been realised.

Important! Please read before the upgrade of the commercial version.

To transfer licence 2.x to 2.5, you must deactivate the licence 2.2 before uninstalling the software. Then, uninstall the previous AutoFEM version, install AutoFEM 2.5 and activate the software anew using the same serial number. To deactivate the licence, use a special command in the AutoFEM folder.

Menu item "Deactivate Licence"

AutoFEM Analysis 2.0 build 5670 (09 October 2013)

The problem of opening files DWG from Windows Explore or from lessons of AutoFEM Analysis Tutorial, while AutoCAD is not working, is eliminated.

In the assembly of AutoFEM Analysis 2.0 build 5669 dated 17 Sep 2013, files DWG could be opened with error because of the slowed loading of AutoFEM modules. This problem manifests itself in the assembly 5669, only if AutoCAD has not already been launched while you are doing a double-click in Windows Explore in the file DWG with saved data of AutoFEM Analysis.

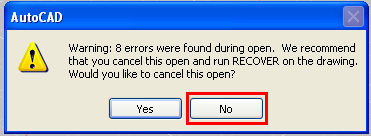

In assembly 5670, if you open a file via the Windows Explore under condition of not launched AutoCAD, you also can see the following message (it may not appear):

It is necessary to continue the procedure of opening the document (press "No"). After AutoCAD will be fully launched, all data of AutoFEM will be accessible for work. All users of AutoFEM Analysis 2.0 build 5669 are strongly recommended that the version should be immediately updated; as the file format was changed (earlier created studies are to be re-created).

ShipConstructor integration module

This optional module is intended to give all users of the ShipConstructor software the opportunity to feel all advantages of the integrated finite-element software solution. Using this module, ShipConstructor users can perform full cycle of engineering calculations (including strength, buckling and other analysis types) not leaving ShipConstructor software.